- -10%

Flexymed by Ergogreen is a bed base manufactured with different body support systems, depending on the area to be supported:

in the shoulder area it is equipped with 3D suspension elements that accommodate the shoulder projection in all positions assumed during rest;

in the pelvis area the wooden slats are equipped with ring rigidity regulators that allow the bearing capacity to be adjusted; this system works like a leaf spring, moving the rings from the centre outwards increases rigidity;

in the lumbar region there are perfect support slats for the curve of lordosis;

the other areas of the body are supported by 25-mm slats that are adapted to conform precisely to the different positions assumed during rest.

Flexymed is available in 3 versions:

Ergogreen's Flexymed bed base is certified as a CE Medical Device in compliance with Directive 93/42/EEC.

The Ergogreen bed frame is designed and manufactured to be long-lasting without deforming. It is made of multilayer beech from FSC-certified forests with mandatory reforestation and recyclable materials.

The frame is 6 x 3 cm thick, this is the section that best fits inside an existing bed, and Catas tests show that it has excellent resistance to vertical static load tests on the edge of the bedspring. Cherry finish frame with Ø 7.5 cm conical legs and a height of 25 cm. Equipped with rubber corner pieces that allow the net to achieve a high level of aesthetic performance and prevent the structure from squeaking because it separates the wooden parts. In addition, the rounded shape and soft rubber cushion any shocks, making the structure safer.

The 3D support elements are installed on wooden slats and are made of TPEE, a tested polymer, which retains its elasticity characteristics even after repeated and lasting stresses.

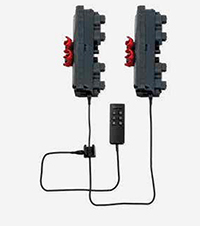

Ergogreen bed bases are available in the version with electric movement, equipped with 2 motors of 4500N, which are fast in lifting and high-performance, silent and also environmentally friendly, as they stand out for their low energy consumption. In the event of a power failure, the net is equipped with an emergency battery that allows the backrest and footboard to be lowered at any time.

It is also possible to equip the bed base with more powerful motors (6500N), or even with radio frequency control.

Ergogreen's Flexymed bed base is also available with an ultraflat electric movement, equipped with two 6500N motors, and characterised by its silence, robustness, absence of metal levers, no encumbrance in the area underneath the bed base, and modern design; these features are reflected in the ease of cleaning, the possibility of installation in any bed without interfering with existing structural elements, and no encumbrance for container beds.

Bed base with standard electric movement:

Ultraflat electrically operated bed base:

Available in the following dimensions:

As standard Ergogreen bedsteads are equipped with 25 cm high conical legs, upon request it is possible to have legs with a height of 30, 35 or 40 cm.

The sled bases can be equipped with the following accessories:

FOOTREST CROSS BAR: The base's feet are mounted on a cross bar which moves their position back.

SIDE MATTRESS STOP ACCESSORY: Sturdy, hooked to the internal frames of the moving bases, it contains the mattresses

CABLE Y STANDARD: Accessory for electrically operated sled bases to raise legs and back at the same time.

STANDARD RADIOFREQUENCY COMMAND: The accessory for electrically operated networks with standard motors is supplied together with the motor that incorporates the receiver and consequently cannot be added later. The control keys are backlit and it is equipped with a night light.

RADIO-FREQUENCY CONTROL FOR ULTRAFLAT MOTORS: Radio-frequency control with courtesy light for ULTRAFLAT motor.

CABLE Y ULTRAFLAT:Accessory for bed bases with ultraflat electric movement to raise legs and back at the same time.

On request it is possible to have the bed base in XXL version, with slats, frame and possibly also a reinforced motor (recommended for persons over 100 kg).

Estimated time for production and product delivery 4/5 working weeks after payment received.